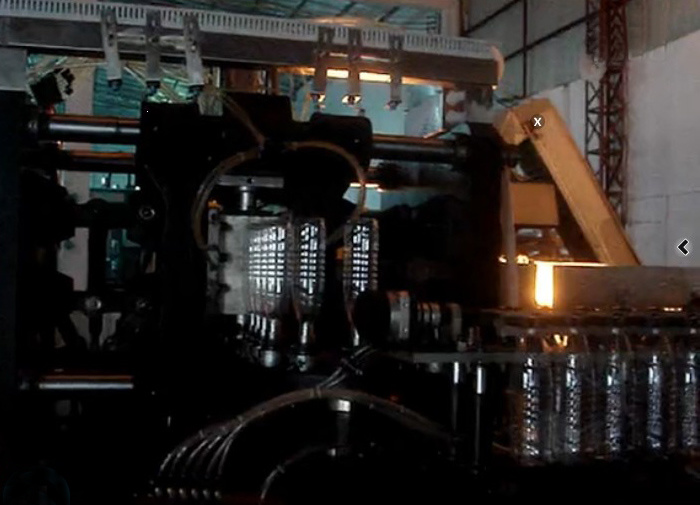

The De Xing One Out Six High-Speed Blow Molding Machine is highly favored in the market.

Publish Time:

2024-12-30

Fully automatic one out six blow molding machine - Dexing manufactures for you

Dexing Machinery's research and design of fully automatic one out six high-speed blow molding machine

Shenzhen Dexing Machinery Co., Ltd. is a well-known manufacturer of hollow molding machines in China, integrating design, production, sales, and service. It professionally provides a complete set of solutions for blow molding machine series products and is one of the well-known suppliers of complete solutions for PET series products in China, sincerely providing customers with production and planning of blow molding machine series products, from preform design to blow molding.

1. Features of Dexing high-speed fully automatic one out six blow molding machine:

1. The entire production process is fully automated, with advantages such as low investment, high efficiency, easy operation, simple maintenance, and safety.

2. Unique heating system with accurate temperature control, simple and quick adjustment. It uses infrared lamp tubes for heating, with strong penetration, preform self-rotation for heating, and orbital revolution, ensuring uniform and fast heating. The width and height of the lamp tubes and reflectors in the heating area are adjustable to suit different preform structures, and there is an automatic temperature discharge device to ensure constant temperature in the drying channel.

3. Independent and simple linear operation system.

4. Uses an automatic conveyor system, allowing for quick and convenient automatic preform delivery.

5. Advanced PLC fully intelligent computer control, lightweight and simple control panel, touch screen display, easy and reliable operation.

6. All actions are driven by cylinders, without using oil pumps, which has the advantages of being pollution-free and low noise.

7. The bottle scrap rate is less than 3%;

8. Uses high pressure and double-arm connecting rod locking mold, with strong locking force;

9. Two modes of operation for blow molding: manual control and fully automatic computer operation, flexible and convenient;

10. Safe and reliable unique valve position design makes the air circuit clear at a glance;

11. The air circuit design separates actions and blowing into three parts to meet the different air pressure requirements for blow molding and actions.

2. Advantages of Dexing DX600-VI product

1. Linear structure, modular design, easy and convenient maintenance;

2. Human-machine interface control, simple operation;

3. Drawer-type mold fixing structure, quick and easy mold change;

4. Reasonable machine structure, good stability, low noise;

5. Semi-closed heating structure, uniform heating of preforms, low scrap rate;

6. The mold closing mechanism uses dual-axis linear guide rails, with a four-template mold closing structure, fast speed, and stable operation.

7. The entire machine frame uses international quality solid steel plates, ensuring stable quality. The templates and the entire machine are annealed, and all flat surfaces and holes of the frame are completed in one go at the CNC processing center, ensuring the frame is firm, not deformed, well-balanced, and all holes and flat surfaces are precise;

8. All accessible parts of the equipment are equipped with safety emergency protection devices to ensure safe production and eliminate human safety factors;

9. The bottom mold design uses a template linkage mechanism, which can increase the output by about 5% compared to similar products in the industry.

10. The main drive uses servo drive, with high production efficiency and lower noise.

3. Characteristics of Dexing DX600-VI machine

1. Single machine capacity can reach 6000 bottles/hour, maximum blowable bottle size is 0.6L;

2. When the necks are consistent, changing bottle types and quickly changing molds only takes 30 minutes;

3. Mechanical oil pressure mold closing structure, more stable and durable;

For details, please call: Shenzhen Dexing Machinery Co., Ltd.

Address: Building A, Unit A, Anlibang Technology Park, Xitian First Industrial Zone, Gongming, Shenzhen, Guangdong Province

Contact: Zeng Wanming 13823568901

Tel: 0755-23425360

Recommended News

Business scope: Production of plastic packaging machinery and equipment, manufacturing of ready-to-drink water filling equipment, manufacturing of bearing gears and transmission components, manufacturing of gas compression machinery, molds and injection-molded preforms. Manufacturing of water resource treatment equipment, high and low voltage switchgear manufacturing, transformers, etc. Agency sales of servo motors and PLCs.

Tel:

Email:

Address:

No. 6, Yichun Avenue, Yichun Economic and Technological Development Zone, Yichun City, Jiangxi Province

Quick Links